There is such a car brand in the island nation Japan. It was born in a cotton spinning factory. At the beginning, it adhered to the credo that imitation was simpler than creation. It can always find breakthroughs in ever-changing markets and crises. It had created many sales myths. And on this basis, it had further created its own luxury car brand, which is Toyota. In this long history of more than 100 years, how exactly did Toyota go from scratch, from small to large, and from weak to strong?

● Toyota brand was born (1895-1937)

A brand emerging from the textile mill

◆ 1895-1931: Toyota’s first engine successfully developed

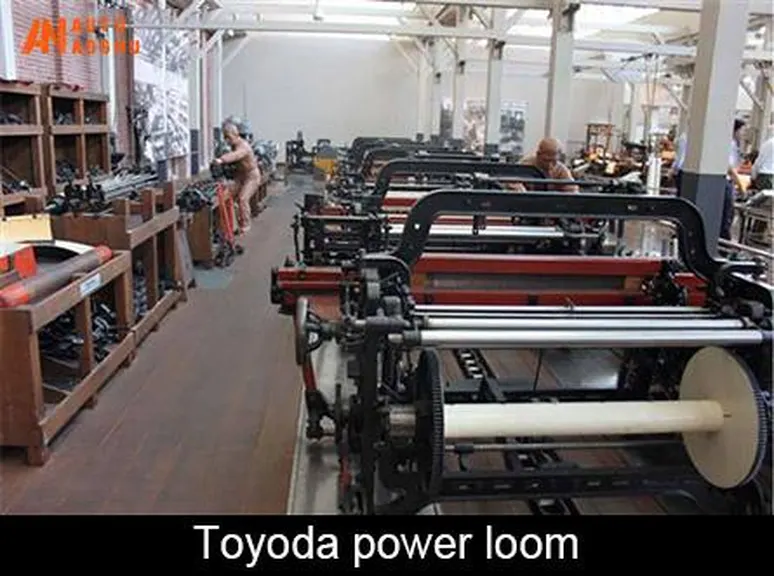

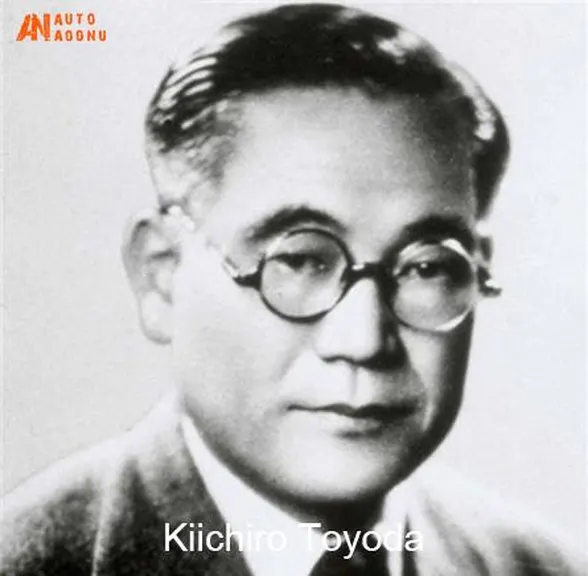

Toyota’s founder, Kiichiro Toyota, was born in 1895. His father, Sakichi Toyota, is both a well-known Japanese textile king and a well-known “inventionist.” In 1896, the 29-year-old Sakichi Toyota invented the “Toyoda power loom”. The loom he invented was not only the first automatic loom in Japan without manpower, but also different from the previous loom in that this loom can take care of 3 to 4 machines at the same time by a worker, greatly Increased productivity. Even Platt, the world’s number one textile machinery manufacturer at the time, also issued a request to Sakichi Toyota for the transfer of patent rights. In the end, Sakichi transferred the right to use of the patent for 100,000 pounds in 1929. This 100,000 pounds was the capital that Kiichiro Toyota used to create Toyota.

In 1929, Sakichi Toyoda sent Kiichiro Toyota to the UK to sign a contract with Pratt. In the process, Kiichiro Toyota also spent four months experiencing British automobile traffic, visited British, American, and especially American automobile production enterprises, and thoroughly Understand the automobile production status in Europe and the United States. He was very impressed by this trip abroad, and strengthened his determination to develop his own car business. After returning to home, he began to study cars.

In 1930, 63-year-old Sakichi Toyoda died. In the automobile industry at that time, American General Motors and Ford Motor Company had already become world-renowned big companies. In terms of mass production technology and market operation, the strength of the two companies is enough to make all other auto manufacturers in the world unmatched, and each opened its own automobile assembly plant to Japan. However, Kiichiro Toyota did not take too much attention to the actions of the two major American car giants. He devoted himself to the domestic automobile industry based on mass production. Finally in 1931, Kiichiro Toyota successfully developed the first 4-horsepower automobile engine.

◆ 1932-1937: Obstructed by many parties, the new plant nearly closed

In 1932, Kiichiro Toyota continued his automotive research. In 1933, Kiichiro Toyota set up an automobile department at a textile factory, and designated a corner of a warehouse as a place for automobile development. Based on this, Kiichiro Toyota purchased a US “Chevrolet” automobile engine in April of that year for repeated disassembly, research, analysis, and mapping. In the process of studying this engine, he came up with the philosophy to guide the company’s future development strategy: “Poor Japan needs more home-based cars. It is my responsibility to produce cheap cars.”

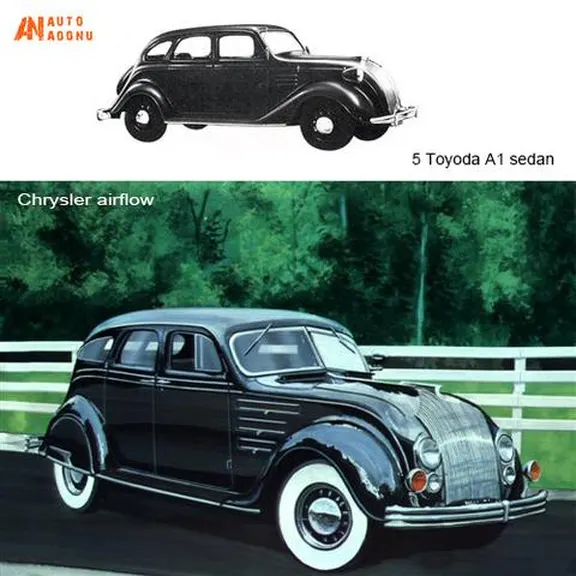

He consigned others to purchase a German-made DKW (one of Audi’s predecessor automobile companies) front-wheel-drive cars from abroad. After two years of research, the first A1 sedan and G1 truck were built in August 1935. Among them, A1 is a large car with a streamlined casing and beautiful appearance. It imitated the Chrysler airflow model at that time and is equipped with a 6-cylinder 3.4-liter engine with an output of 62 horsepower (46 kW). Prior to this, in 1934, he purchased about 180 hectares of land, and was actively preparing to create a car factory.

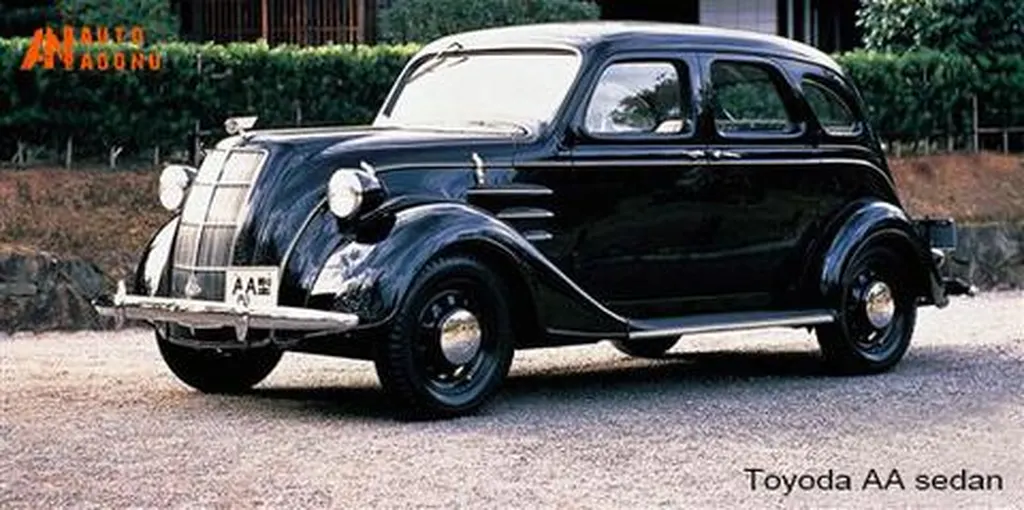

In 1936, in the newly completed plant, the AA sedan (improved from the A1 sedan) began production, initially producing only 150 cars per month. One year later, in 1937, Toyota produced a total of 4,013 cars, of which only 577 were AA cars and AB convertibles. On August 28, 1937, the Ministry of Automobile announced that it would become independent from Toyota Automatic Loom Manufacturing Co., Ltd., and established “Toyota Motor Co., Ltd.” Toyota Motor Co., Ltd. is located in Juta-cho, Aichi Prefecture, with a capital of 12 million yen and more than 300 employees.

After the establishment of the new company, Kiichiro Toyota, who held firm confidence in the Japanese automobile industry, ignored the surrounding opposition and decisively decided to invest another 45 million yen to build a production system with a monthly output of 2,000 vehicles. This huge investment is almost equivalent Four times the company’s capital. Because of this, when Toyota Motor Corporation was just established, it immediately encountered a crisis that almost closed it down. At that time, the world economic crisis that engulfed capitalism had a strong impact on the Japanese economy. The construction of the main plant, the introduction of equipment, and the procurement of raw materials required a lot of capital, and the models made by Toyota at the time still had defects in quality, so sales also Not good, and at this time the initial investment has been exhausted, and the company has at the end of it’s rope. At this time, the war of aggression against China broke out. Toyota, along with many other manufacturers, was included in the production track of wartime military industrial products. The Army purchased all its stock trucks at once, which helped it escape the crisis.

● Preliminary development of Toyota (1938-1954)

Started from imitation, promote diversified products for the Japanese local market

◆ 1938-1954: Persevering in imitation is simpler than creating, and is involved in many fields such as electric vehicles, passenger and freight cars, SUVs, etc.

In 1938, Toyota’s original site could not meet production needs. From this year, Toyota Motor Industry Corporation moved the factory to Koromo city, which is today’s Toyota Headquarters plant. Later, the Koromo city was rapidly developed due to the existence of Toyota, and then it was directly changed to the current Toyota city.

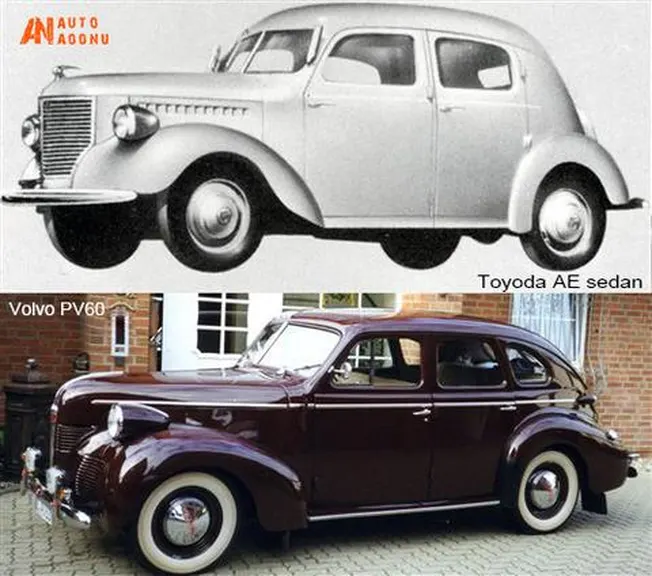

Japan is a country with scarce natural resources, so Toyota Kiichiro believes that the development of cars with High burn up power, reliability and durability is a crucial issue for the Japanese automotive industry. In 1939, the company set up a battery research institute and began the development of electric vehicles. In 1940, Toyota produced about 15,000 cars, 98% of which were trucks. That year it introduced a new compact AE sedan with a 4-cylinder 2.2-liter 48-horsepower engine, which is closer to Volvo’s pv60 in appearance.

Though Toyota doesn’t have much experience with cars, it adheres to a tenet: imitation is simpler than creation. If imitation can be improved at the same time, it is better. Kiichiro follows his father’s philosophy. He knows that the first must be to produce safe, solid, economical and traditional cars, not innovative products. So for a long time, all Toyota cars have such characteristics.

In December 1941, the Pacific War broke out. By the end of World War II in August 1945, Japan’s industrial production facilities were almost destroyed, and Toyota’s factories were severely damaged during the war. In the few years after the war, the Japanese economy was in a state of chaos. The employees of the company were deeply worried about the development prospects of the Japanese automobile industry, which was already quite backward. In order to use the automobile industry as a pillar industry for peacetime economic development, Kiichiro Toyota completed the rebuilding of the plant. At the same time, in September 1945, Toyota decided to build a small car factory based on the original truck mass production system. This decision was made mainly because the United States does not sell small cars in Japan, hoping to avoid direct competition with American car brands. In January 1947, the prototype of the first small car, Toyota SA, was finally successfully produced. According to the principles of fluid mechanics, this prototype car uses a streamlined body and spine frame structure, and is equipped with a four-wheel independent suspension structure to become a new body mechanism, with a maximum speed of 87 km / h.

In 1951, the Japanese Police Reserve tendered a small off-road vehicle project to Japanese auto factories. Toyota introduced the BJ series off-road vehicles at that time, and the body adopted a canopy. As a result of the climbing test of Mount Fuji 6th Station, the BJ series proved its off-road and durability. Therefore, this car was not only welcomed by the police reserve team, but also continuously produced and expanded since then. This is the originator of today’s world-renowned land cruiser series. In addition, Toyota has taken advantage of the sharp increase in demand for taxis to accelerate car production. By 1953, the previous production capacity of about 50 vehicles per month had been increased to more than 250 vehicles, and Toyota began to enter a period of rapid development.

◆ Innovative production mode of Toyota: more professional / higher efficiency than traditional production mode

On March 27, 1952, Kiichiro Toyota died of cerebral hemorrhage. In fact, when Toyota Kiichiro was alive, Toyota had formed a scientific production model. Its innovations include: internal adjustments of the company, the classification of parts and components, and a storage mode that produce and use. First of all, in terms of internal adjustments of the company, the Shincheon plant under Toyota was changed to Aichi Steel Corporation. Machine Tool Production Department was changed to Toyota Machinery Company. Shincheon Plant was changed to Aisin Precision Machinery Company. Body Department was changed to Toyota Body Company. Electrical Installation Department was changed to Japan Electric Installation Company. After the adjustment, the company realized the specialization, rationalization and scientificization of its own structure, thereby changing the chaotic production pattern of the unification.

Secondly, in the classification of parts, in the production process, all parts used in the assembly of automobiles are divided into two categories: internal products and purchased products. Among them, internal products are divided into internal manufacturing parts (Great technical difficulty and high purchase price) and quasi-internally manufactured parts. The purchased products are divided into three types: general external order, particular order, and special order. As a result, the work goals of each department have become clearer, which has greatly improved work efficiency.

Third, Toyota has also formed a new storage model. According to the traditional practice, automobile production must be put in storage from castings to semi-finished products, and then picked up and processed when needed. The processed parts must also be put in and out of the warehouse according to the needs of the factory. Acting in accordance with this procedure has increased the demand for inventory virtually. Toyota’s innovation lies in changing traditional batch production methods to flexible production methods. Produce and use, producing only the parts needed, the factory does not need to set up an inventory warehouse, does not need to occupy a large amount of working capital, and many outsourced parts are already sold on the car before payment. After such a production model was further developed by the company, it became a perfect “Toyota production method”. Today, the “Toyota Production Method” has transcended nationality and industry and has become an advanced experience that many countries in the world are eager to learn.